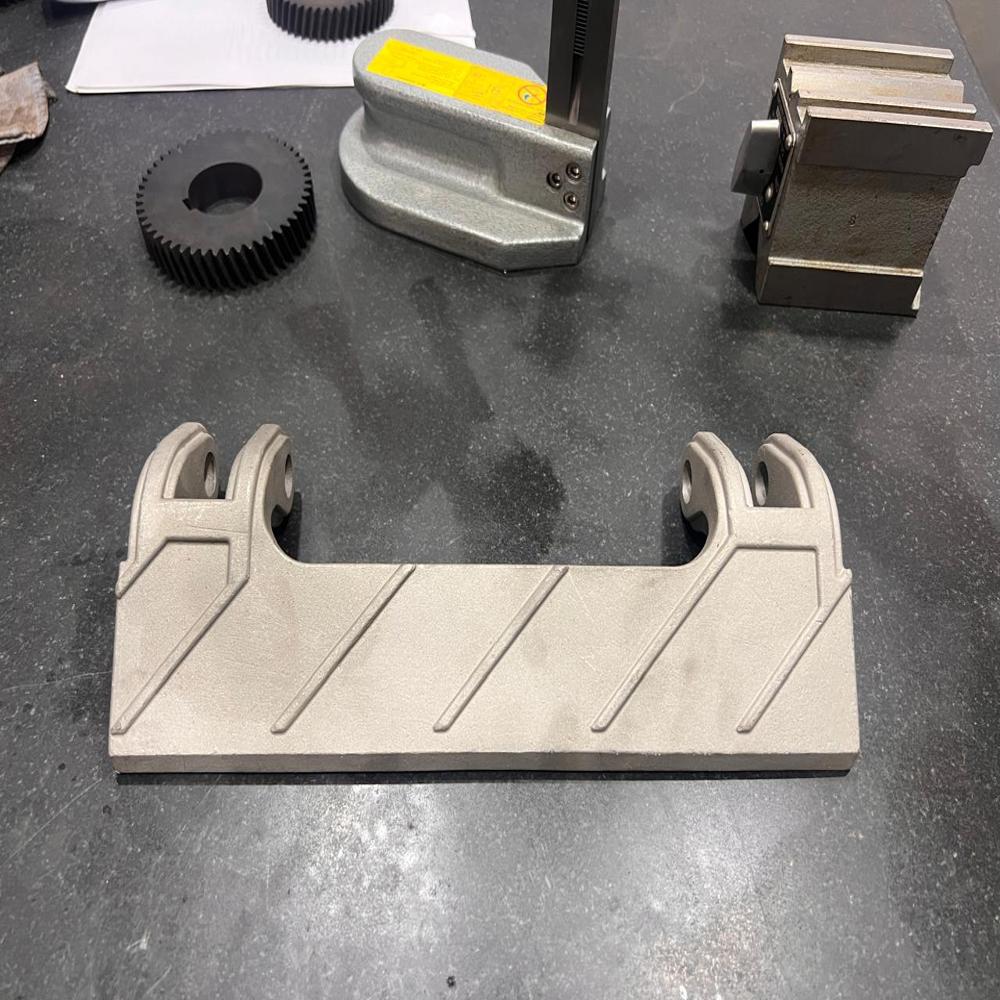

ATFD Blade - Agitated Thin Film Dryers

Price 900.0 INR/ Number

ATFD Blade - Agitated Thin Film Dryers Specification

- Product Type

- Investment Casting Components

- Material

- Stainless Steel

- Color

- Silver

- Warranty

- 1 Year

ATFD Blade - Agitated Thin Film Dryers Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- Ahmedabad / Mundra

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 10000 Per Month

- Delivery Time

- 1

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- as per standard

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About ATFD Blade - Agitated Thin Film Dryers

ATFD Blade - Agitated Thin Film Dryers :Engineered for Precision and Durability

Crafted from top-quality stainless steel with a polished finish, the ATFD Blade ensures excellent resistance to corrosion and mechanical wear. Its solid construction delivers stable, long-lasting operation, even in demanding industrial environments. This attention to design and materials ensures the blade can effectively handle a range of thermal and mechanical stresses during drying processes.

Trusted by Multiple Industry Players Across India

As a dealer, distributor, exporter, manufacturer, service provider, supplier, trader, and wholesaler, the provider network in India offers robust sales and ongoing support. Customers benefit from comprehensive service coverage, expert technical guidance, and streamlined delivery to both domestic and international markets.

Optimized for Efficient Thin Film Drying Processes

The ATFD Blade is designed for seamless integration into Agitated Thin Film Dryers. Its precise engineering supports uniform film formation, promoting rapid moisture evaporation from challenging materials. This technology is favored in pharmaceutical, chemical, and food industries for its energy savings and gentle handling of sensitive substances.

FAQs of ATFD Blade - Agitated Thin Film Dryers:

Q: How does the ATFD Blade function within an Agitated Thin Film Dryer?

A: The ATFD Blade promotes uniform spreading of materials into a thin film across the heated surface within the dryer. Its agitation ensures even heat distribution, enabling efficient drying by facilitating rapid evaporation of moisture from the processed material.Q: What materials can be processed using the stainless steel ATFD Blade?

A: This blade is crafted from stainless steel, making it suitable for processing a variety of substances, including pharmaceuticals, chemicals, food ingredients, and other heat-sensitive or viscous materials that require gentle yet effective drying.Q: When should the ATFD Blade be replaced or serviced?

A: Routine inspection is recommended, but under normal operating conditions and with proper maintenance, the stainless steel ATFD Blade can function efficiently for extended periods. The product includes a 1-year warranty, ensuring manufacturer support during this time.Q: Where is the ATFD Blade supplied from, and can it be shipped internationally?

A: The ATFD Blade is produced and distributed mainly in India by multiple providers such as manufacturers, distributors, suppliers, and exporters. It is available for both domestic procurement and international export.Q: What is the process for installing the ATFD Blade in existing equipment?

A: The ATFD Blade is engineered for compatibility with standard Agitated Thin Film Dryer assemblies. Installation involves securing the blade in position within the dryer, following manufacturer-provided specifications and safety guidelines to ensure optimal operation.Q: How does the polished surface benefit industrial applications?

A: The polished stainless steel surface not only enhances the blades resistance to corrosion but also aids in easy cleaning and maintenance. This helps prevent product contamination and supports industries with stringent hygiene standards.Q: What advantages does the ATFD Blade offer over other drying mechanisms?

A: Compared to conventional dryers, the ATFD Blade enables gentle, efficient drying of heat-sensitive materials, reduces energy consumption, and minimizes product degradation. Its robust stainless steel construction further ensures reliability in continuous industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Investment Casting Category

Precision Investment Casting

Price 300 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Investment Casting Components

Color : Silver

Surface : Polished

Application : Other

Agricultural Castings

Price 300 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Investment Casting Components

Color : Silver

Surface : Polished

Application : Other, Industrial

Aluminum Die Casting

Price 400 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Investment Casting Components

Color : White

Surface : Polished

Application : Other, Industrial

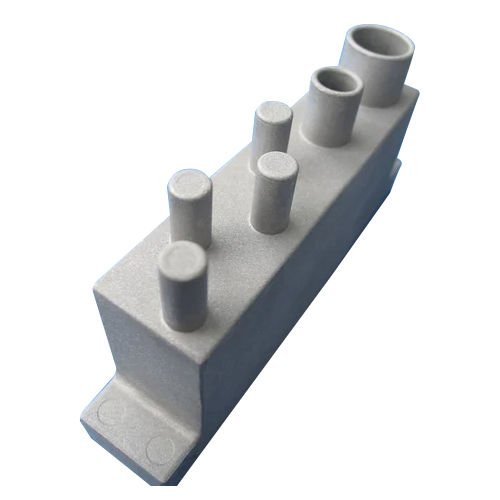

Block Connector Defence Casting

Price 200 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Investment Casting Components

Color : White

Surface : Polished

Application : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry